Walk the Line: Daniel Leech from TDS Group

We caught up with Daniel Leech, Group CEO from TDS Group, to talk about international projects, innovation and the future workforce in construction.

Daniel Leech

Group CEO

Technical Design Services Group

Listen to the interview here, or read on below….

Dan, could you tell us a bit about yourself?

“I’m the CEO of the Technical Design Services Group (TDS).

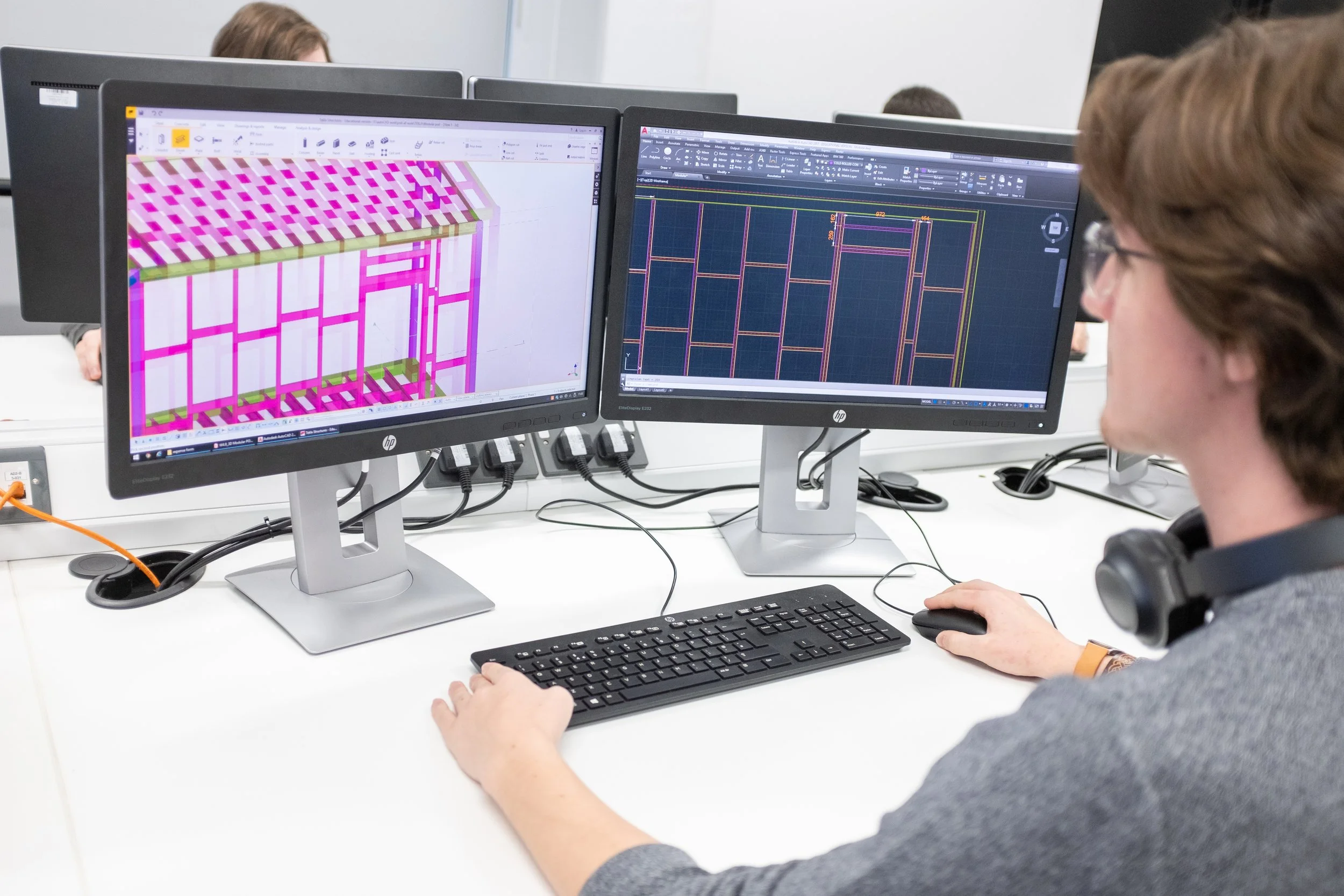

We consist of three brands. The first is a structural engineering consultancy called Design4Structures, which does everything from underground drainage through to foundation design and substructure, all the way through to construction engineering. The second is the TDS team, which is a detailing business. We provide manufacturing companies with BIM-compliant modelling and detailing for heavy, hot-rolled structures, light gauged steel and modular volumetric developments. The third of the three businesses is CADCOE, the Construction and Design Centre of Excellence, a training provider which supports people into careers within design engineering. CADCOE also delivers a formal digital design technician apprenticeship in partnership with leading UK FE colleges and providers.

As a group, we’re working within the professional services part of the construction industry and get involved in a variety of diverse projects from airports to stadiums, residential schemes to student accommodations.

How much of what you do is offsite?

In the past, it has probably made up about a third of the work that we do. But, in the last 12 months, we've noticed a sizable shift to around 60–70% of the projects we’re working on having at least an MMC slant, whether that be in the form of volumetric modular construction, or an SFS (Structural Framing System) infill, for example.

“I think the offsite and modular markets have been threatening to explode for several years, and now the momentum is finally starting to build.”

It feels like a bit of a buzzword. Some clients ask for MMC, but don't understand what they're asking for, or why they're asking for it. I also think a lot of it is due to the speed at which we need to construct. For example, on the modular volumetric side, when it comes to residential housing, we're falling way short of the government target for the number of homes that need to be built and constructed. It seems like a natural fit; some of the issues we've got around the speed at which we can build homes can be solved by offsite.

Terminal 2 at Hong Kong Airport

Could you tell us about the successes you’ve had in the last 12 months?

For the first six months of the pandemic lockdown, we were primarily finishing off our work on Terminal 2 at Hong Kong Airport which we delivered in a completely new way. Rather than working for the manufacturer, we worked directly for the Hong Kong Airport Authority. They saw huge value in developing the digital asset far earlier in the process, which gave us a lot of scope and flexibility to innovate and spend time on code and script. It enabled us to develop things like parametric modelling tools, something we wouldn't have the opportunity to do in the UK market because of the way that projects are procured, the risks associated with what we do and how tight the programs are. That was a big success in strategically positioning the business in the right place.

After that, we began working on a project this time last year for Waites - the ‘Piccadilly Lights’ building at One Sherwood Street - which again for us was positive knowing that we've got a UK-based main contractor that can see the value in developing the digital asset and bringing us in to deliver as a structural engineer that can detail, through the links between Design4Structures and TDS. We believe that being able to deliver everything from RIBA stage zero all the way through to stage five can create tremendous value in projects.

‘Piccadilly Lights’ at One Sherwood Street

Is a large part of what you do international, or is Hong Kong a standout project for you?

We’ve been involved in multiple international projects, we've worked in both Canada and North America and have done industrial projects in Korea. We have also worked on Los Angeles Airport and a couple of large-scale distribution centres in America. I think that the way the technology has evolved, in addition to Cloud-based modelling, has opened up what we do across international markets.

I would argue it is probably as big a threat as it is an opportunity for us, because a lot of the work that we do, particularly on the steel detailing side, does seem to be finding itself going overseas to very, very, unsustainable rates compared to the UK market. But certainly, I think there are international opportunities, because of the way that technology works now: video calls are commonplace. As recently as two years ago, a lot of people would look at you like you've got two heads if you asked them for a video call, so for us, like so many companies, that has been a real positive development.

Looking ahead to the next 12 months, what do you expect to be working on?

It's a very mixed bag. For us, enquiry levels have never been higher. Just last month we tripled the highest number of inbound inquiries that we've ever had as a business in our twenty years.

We're expecting to see quite a big increase in the construction of data centres and large-scale distribution centres, for things like electric vehicles and batteries. Obviously, the success of Amazon and companies with similar models has gone through the roof, particularly over the last couple of years with the pandemic. So, we're expecting to see lots of large-scale distribution centres being built and constructed. We're hoping that the MMC market also grows and that standardised, or industrialised, products start to come onto the market.

Do you think that working on a variety of project types gives you an advantage?

Very much so. I think what makes us unique as a professional services business is that we're not looking to sell a particular product or a particular system. We're not leaning towards concrete or light gauge steel because we're looking to manufacture that product or system. What's important is the right solution for the right project. We have so much diversity within the team, from those who have experience in high-value residential projects, to those who love traditional residential projects.

It can also be a little bit of a challenge. If one particular area of the market goes quiet, it's very difficult to reutilise those with specific niches in other areas of the business, but as a company, we always work to re-engage and move people around onto new projects.

We’re also able to utilise this advantage when working across international projects, for example when the pandemic hit, we provided services to companies in India who didn’t have the infrastructure set up to work from home. We’re so pleased to be able to tap into wider markets, but we have got to make sure that we don't damage the UK industry by racing for the cheapest price overseas, something which I think the construction industry has always traditionally done.

What’s the opportunity for technology in offsite at the moment?

I think we have a fantastic opportunity to use technology as a vehicle for attracting young talent into the industry and I also think there is potential to cross-pollinate from other industries. But, I think there is a real cultural block and risk-averse mentality. The industry seems excited by this new, evolving technology, but the reality is that on the front line of delivering the live construction projects it is just not being utilised to its full capability.

“Main contractors and clients say that they want their supply chains to innovate and collaborate, but the contracts and programs that you’re expected to sign up to and the rates that you’re expected to work for, don’t create an environment of innovation, because in simple terms, you’re not given enough time or money.”

You could try to be innovative during a project, but if it goes wrong, you are monumentally exposed to liquidated damages, back charges and counter-charges, so it becomes risky to try new things.

That said, some exciting technologies are having a positive impact on our work. I’ve mentioned how incredible the introduction of virtual calls has been for us, using platforms like Microsoft Teams. We’re all now also communicating on shared channels and chat threads, which is far, far easier to keep everybody in the loop.

I also think that the developments in augmented and virtual reality are exciting, for example, we've been on projects where virtual reality headsets are used to actually walk around and review a model. I know older members of the team still like drawing models by hand, but if we're going to attract the next generation of young people, then we've got to get used to communicating and working in an environment that's going to appeal to them.

Similarly, we’ve found that when recruiting we were initially calling people and being frustrated when they didn’t answer the phone. But, when we sent emails or WhatsApp messages we would get an immediate response. I think it is important to recognise that the landscape is changing and you've either got to run with that and change the way that you do things or risk becoming obsolete.

There is so much room for technological development, but I just hope that we're all afforded the time and money to invest in these things. There is not only a significant investment required in software and technology, but you've also got to upskill your people to be able to use it effectively. It feels to me like the construction industry needs to slow down, take stock and look at how we are working before it can then speed up again.

From the perspective of a training company, what do you see as the solutions for the skill shortages?

I think the industry needs to prioritise partnering with the educational establishment. I've got a tremendous amount of sympathy for colleges, universities and schools; the salary for teaching the job is considerably less than the salary for doing the job. So, you end up with people at the tail end of their careers as the ones who go to the classroom.

But, young people can and will learn from other young people. It doesn't need to be someone who has 40 years experience showing someone how to utilise a piece of software or hardware. It is important to work with the educational bodies to develop the curriculums that they need and want, to also help deliver those curriculums, and to find new platforms for teaching and delivering the training that the industry needs.

I think the biggest sense of pride that we get from everything that we've delivered at CADCOE is that we've attracted, recruited, trained and introduced over 500 young people into the industry over the last 10 years. So, we feel like we've contributed to improving the skill shortages in the area of the market that we work in.

What’s the biggest challenge for construction at the moment?

“I think my biggest concern is that if we don’t change, people are going to leave in droves.”

I think we've got to make the environment a more hospitable, nicer place to work, and less of a constant battle. I think that's a real challenge.

With the rising awareness around mental health over the last couple of years, there has been an enormous shift.

“The best way I can put it is that if the construction industry was a friend, or a wife or a husband, you’d probably get rid of them.”

I think there is a huge opportunity to change that, but I think it will be a generational shift and that the younger people, over the next 5-10 years, can help to change it for the better.

And to end, who are you passing the mic to next?

“I’m passing the mic to Richard Hyams at Astudio Architects and Ben Haldin at Fulcro. They would both have plenty to say and be very interesting guests for your listeners!”